Logistics and Storage 3D Modeling Service Advantages

Focused on logistics and storage industry characteristics, providing professional, accurate and efficient 3D modeling solutions

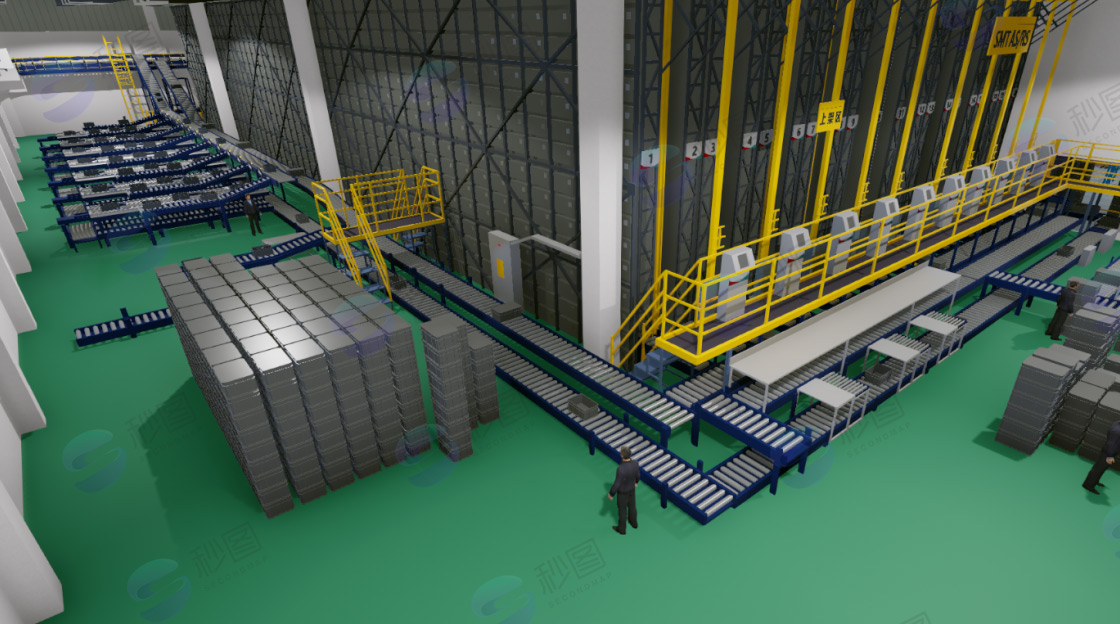

Full Element Coverage

Covering storage facilities, equipment, materials, and operational processes to build a complete digital twin storage environment

Dynamic Behavior Simulation

Supporting dynamic simulation of equipment movement and operational processes, realistically reproducing storage operation status and work processes

High Performance Optimization

Professional optimization for massive shelves and cargo models to ensure smooth interactive experience in large-scale scenarios

Deep Data Integration

Seamless integration with WMS/WCS and other systems to achieve real-time linkage and visualization of business data and 3D scenes