Supported Engines and Application Scenarios

Compatible with mainstream rendering engines and platforms, widely applied in various fields of equipment O&M management, improving equipment management efficiency and maintenance quality

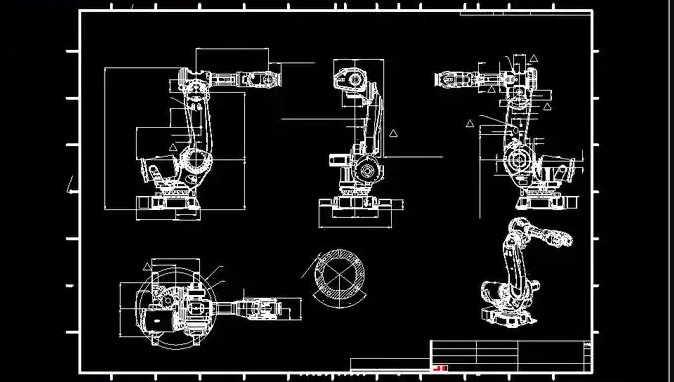

Equipment Digital Twin Platform

Building an equipment digital twin platform, integrating equipment 3D models with real-time operational data, achieving visual lifecycle management of equipment,

providing data support for equipment O&M decision-making, and enhancing the intelligence level of equipment management

Visual Monitoring

Real-time visual monitoring of equipment operating status, automatic abnormal status alerts

Historical Data Analysis

Historical trend analysis of equipment operational data, performance evaluation and prediction

Maintenance Management

Maintenance plan formulation, execution tracking, and maintenance effectiveness evaluation

Intelligent Diagnosis

AI-based intelligent equipment fault diagnosis and troubleshooting solution recommendations