Compatible Subsystem Types

3D models serve as a unified digital platform that can be deeply integrated with key business subsystems to achieve data visualization

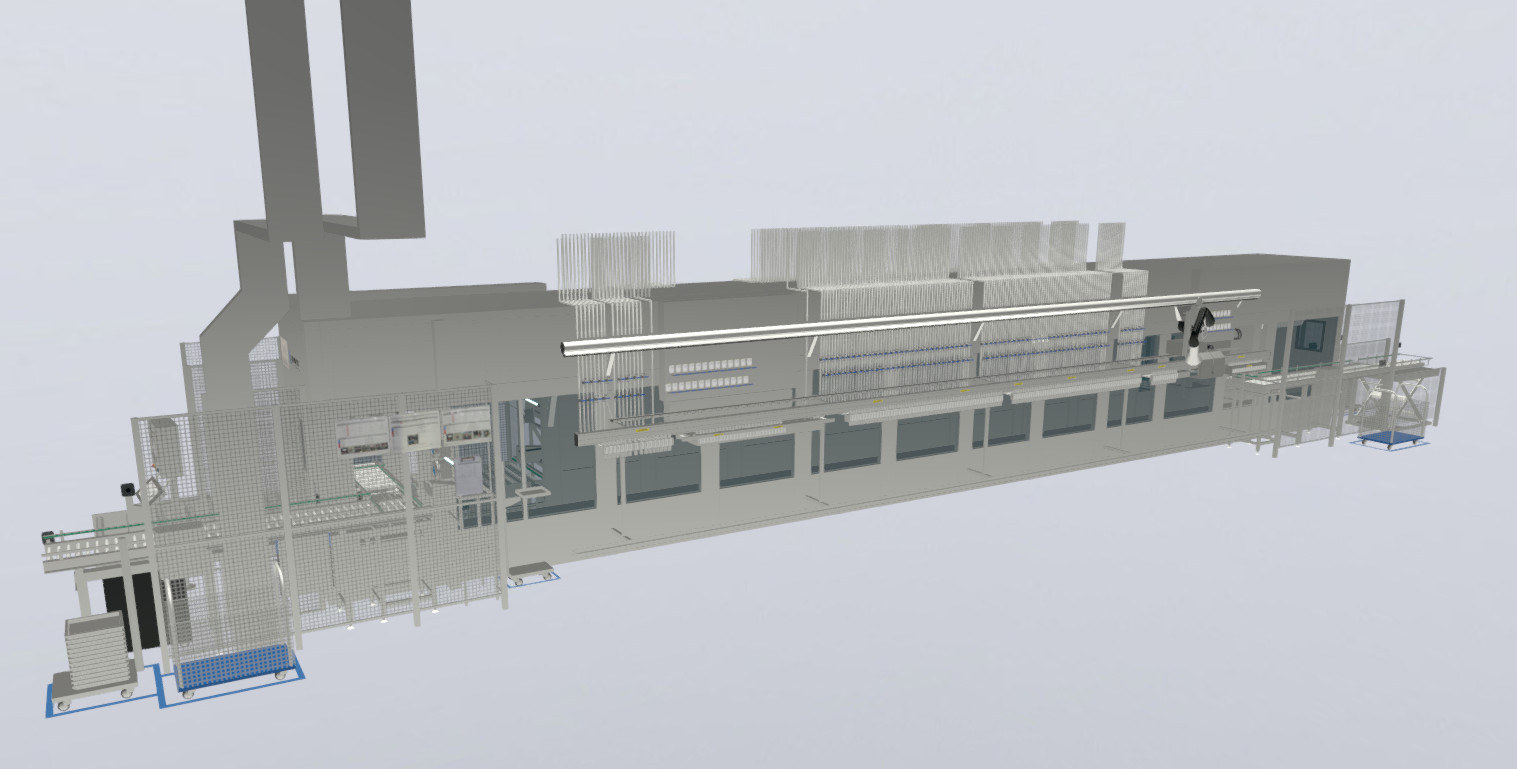

Manufacturing Execution System (MES)

Real-time mapping of production order progress, equipment operation status, material location and other information on the model, achieving visual monitoring and scheduling of the entire production process, improving production efficiency and response speed.

Order Progress

Equipment Status

Production Scheduling

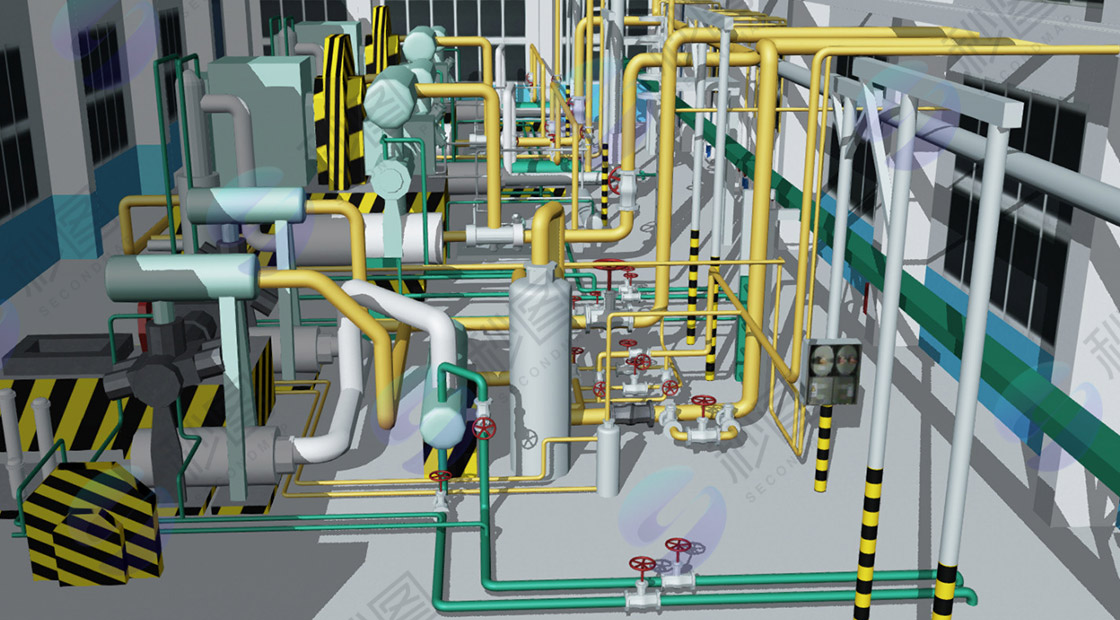

Supervisory Control and Data Acquisition System

Bind equipment, instruments on the model with real-time process data (such as temperature, pressure, flow), achieving transparent monitoring of operating conditions and precise positioning of abnormal alarms, improving equipment reliability.

Real-time Data

Abnormal Alarm

Remote Monitoring

Asset Management System

Link equipment ledger, maintenance history, inspection plans, and spare parts inventory to achieve visual management of the entire asset lifecycle and preventive maintenance, reducing operation and maintenance costs and extending equipment life.

Equipment Ledger

Maintenance Plan

Spare Parts Management

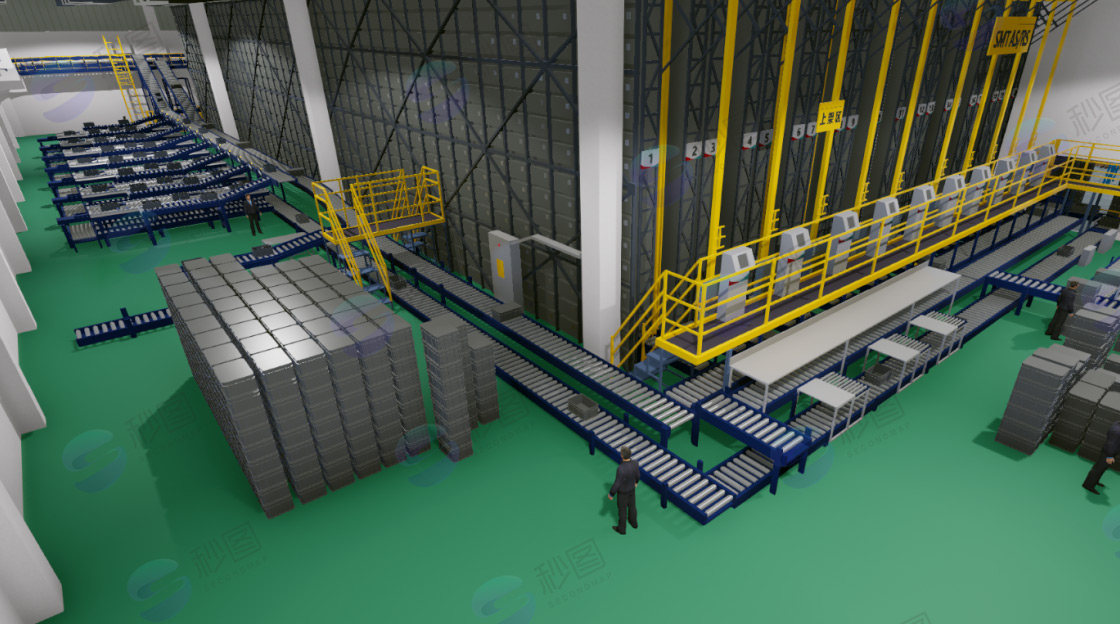

Warehouse Management System (WMS)

Link with automated warehouse, shelf, and AGV models to visualize real-time inventory status, location information, and AGV running trajectories, optimizing warehouse space utilization and logistics path planning.

Inventory Status

Location Management

AGV Scheduling

Personnel Positioning and Safety System

Real-time display of personnel positions in the model, achieving electronic fences, safety warnings, and emergency evacuation simulations, improving factory safety management levels and ensuring personnel operation safety.

Personnel Positioning

Electronic Fence

Emergency Evacuation

Energy Management System (EMS)

Link energy pipelines (electricity, water, gas) with metering instrument models to visualize and analyze energy consumption data and flows, assisting in energy-saving decisions and reducing energy consumption and costs.

Energy Consumption Analysis

Energy Flow

Energy-saving Optimization