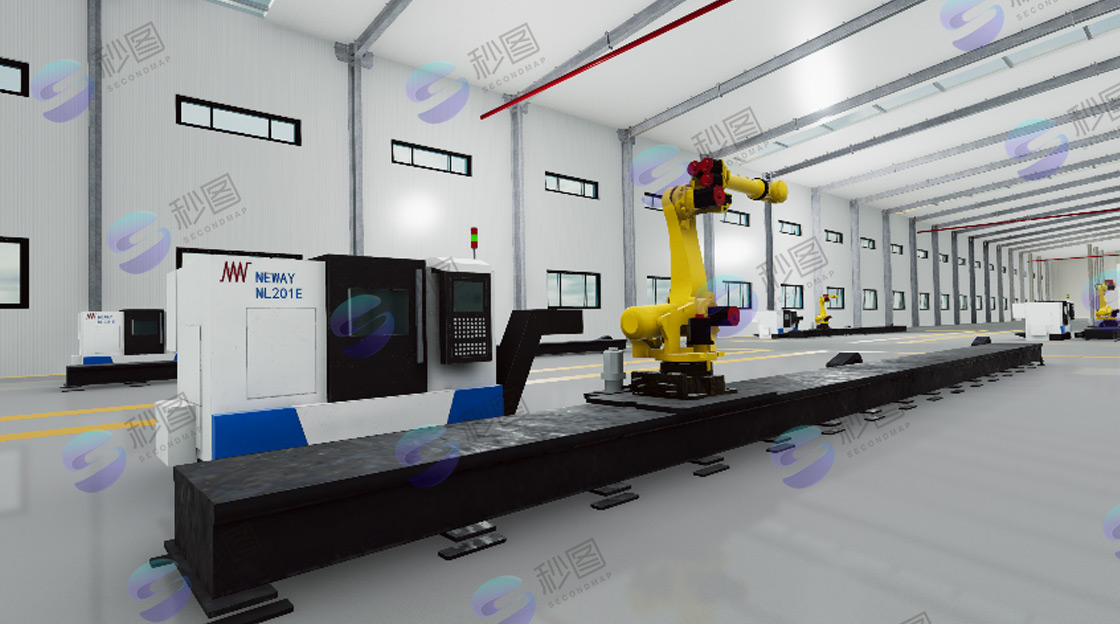

Robot 3D Modeling Service Advantages

Creating high-precision digital twins for robot operation systems, achieving accurate monitoring and efficient management

Professional-Grade Precision

Geometric accuracy error ≤0.5%, ensuring virtual model and physical device dimensions are completely consistent,

providing a reliable foundation for accurate monitoring

Real-Time Data Synchronization

Achieving status synchronization through OPC UA protocol with low latency, each component associated with real-time data,

realizing accurate mapping of real status

Kinematics Simulation

Following ROS system standards, defining physical properties and kinematic parameters through URDF/XACRO files,

supporting precise motion simulation

Efficient Lightweighting

Using LOD technology to optimize meshes, improving Web loading speed, balancing accuracy and performance requirements

Seamless Integration Capability

Supporting direct loading on mainstream digital twin platforms, providing standardized data interfaces for operation systems,

simplifying system integration processes

Interactive Experience

Supporting status visualization and interactive operations, displaying device health status through color coding,

improving operation efficiency