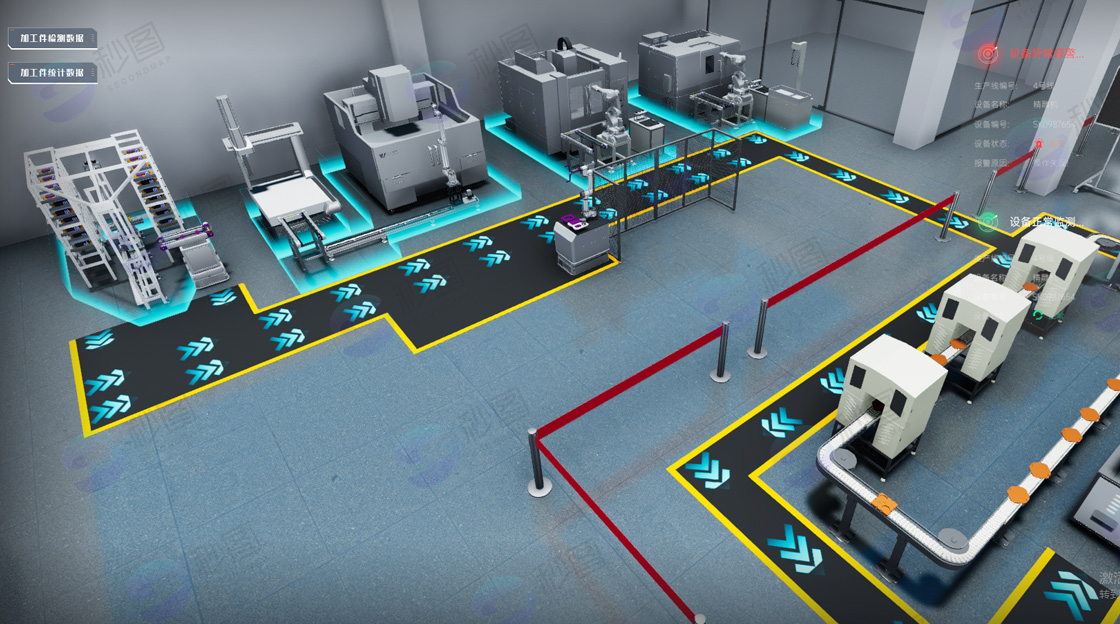

Workshop 3D Modeling Service Advantages

Create high-precision, interactive, and integrable workshop digital twins to empower smart manufacturing transformation and upgrading

Comprehensive Element Digitalization

From building structures to equipment details, from logistics systems to pipeline networks, comprehensively covering all key elements of the workshop

Multi-System Integration

Deep integration with industrial systems such as MES, SCADA, WMS to achieve data visualization and business linkage

High Performance Experience

Professional lightweight processing to ensure smooth rendering and real-time interactive response in large-scale complex scenarios

Industrial-Grade Precision

Strictly ensuring dimensional proportions and spatial relationship accuracy to meet professional needs such as production simulation and spatial analysis