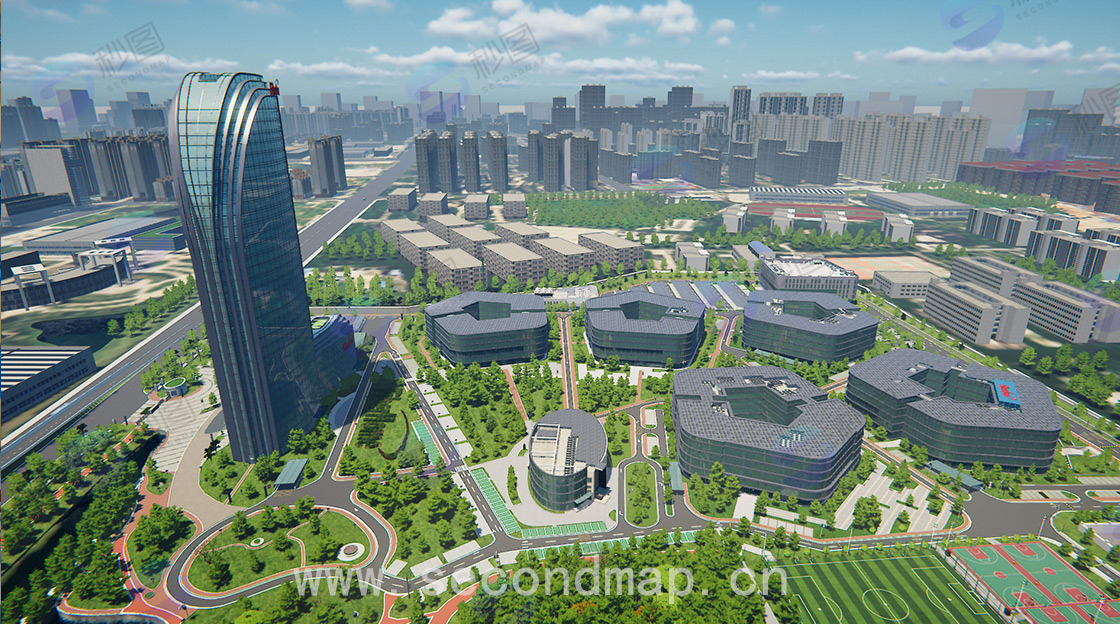

Northern Rare Earth Group Smart Safety Factory

Our 3D model and 3D art project for a rare earth digital factory, created for a branch plant of Northern Rare Earth, have successfully passed acceptance and been delivered. The project utilized multiple surveying and acquisition methods, including drones, laser point clouds, and high-precision digital cameras, to ensure the accuracy of the factory's 3D model met project delivery requirements. During implementation, laser point clouds were used to assist in modeling workshop and equipment 3D models, while high-precision drone cameras were used for low-altitude and low-area resurfacing photography outdoors. This successfully helped the rare earth group complete the implementation and delivery of the 3D digital factory.

We specialize in the digital transformation of rare earth factories, providing full-scenario 3D modeling solutions. Our core services cover factory 3D model building, workshop 3D modeling, rare earth plant 3D modeling, and factory 3D general layout and rare earth plant 3D general layout drawing services, facilitating the visualization upgrade of rare earth production scenarios. Leveraging laser point cloud 3D modeling technology, precise data on factory equipment, workshop layout, and plant topography are collected. Combined with oblique photogrammetry, the overall plant environment is reconstructed. Results can be output at different precision standards (L3 and L4) as needed, ensuring the 3D model accurately matches the production process requirements of rare earth industries in northern China. It clearly presents key details such as workshop equipment connections, pipeline routes, and plant spatial layout. These digital results can be widely applied to rare earth plant planning optimization, production process monitoring, and equipment operation and maintenance management, replacing traditional two-dimensional drawings, solving the problem of fragmented factory information, improving production management efficiency and safety control levels, providing professional technical support for the digital construction of rare earth plants, and promoting intelligent operation of rare earth facilities.