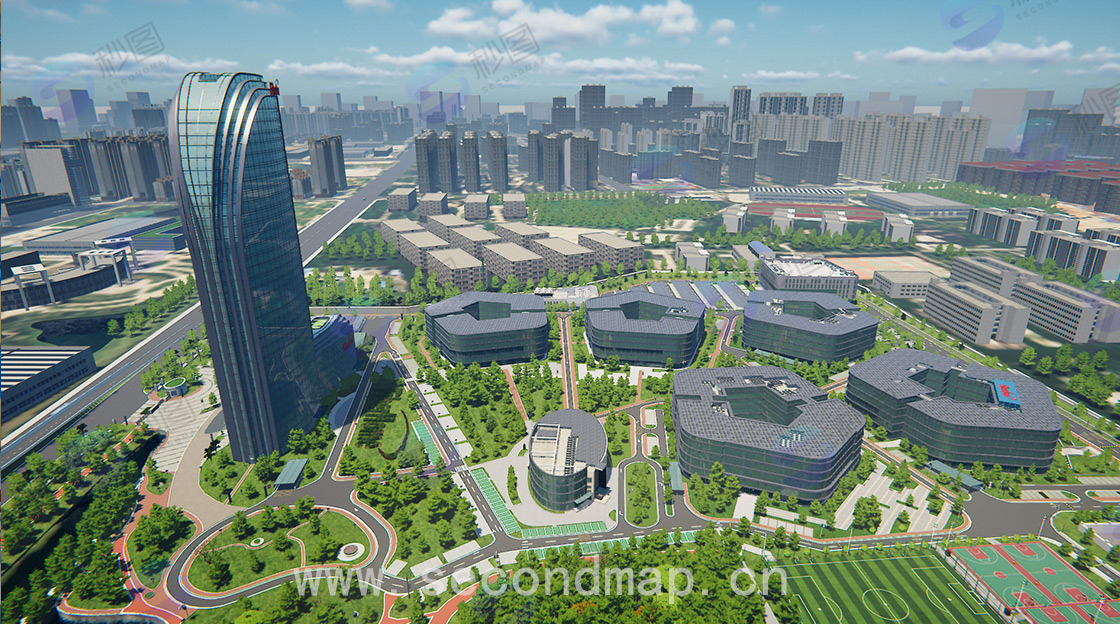

TBEA Smart Technology Industrial Park

We successfully delivered a 3D visualization project for a digital factory to TBEA Group. The project involved Level 3 manual modeling of the entire factory area and Level 4 detailed modeling of key indoor areas of the workshops, achieving comprehensive coverage and control of the entire factory's 3D data, ensuring a clear and traceable understanding of the factory space.

We specialize in 3D digital factory construction, providing end-to-end 3D digital solutions. Our core services include 3D site planning, 3D mapping, and 3D modeling, helping factories transform towards intelligent and smart manufacturing. Leveraging laser scanning technology to accurately collect physical data on factory equipment, production lines, and buildings, combined with high-precision 3D modeling capabilities, we created 3D equipment models, 3D production line scenes, and 3D robot digital models required for TBEA's digital factory, according to different accuracy standards (Level 3 and Level 4), realistically recreating the factory's production layout and equipment operation details. Simultaneously, the 3D site plan integrates global spatial information of the factory, and 3D mapping technology clearly presents production line processes and equipment relationships, providing intuitive data support for intelligent factory operation. These digital achievements can be applied to scenarios such as factory production monitoring and equipment operation and maintenance, breaking down traditional management barriers, improving the production efficiency and control accuracy of TBEA's digital factory, promoting the implementation of smart factory construction, and providing professional technical support for the digital transformation of manufacturing enterprises.