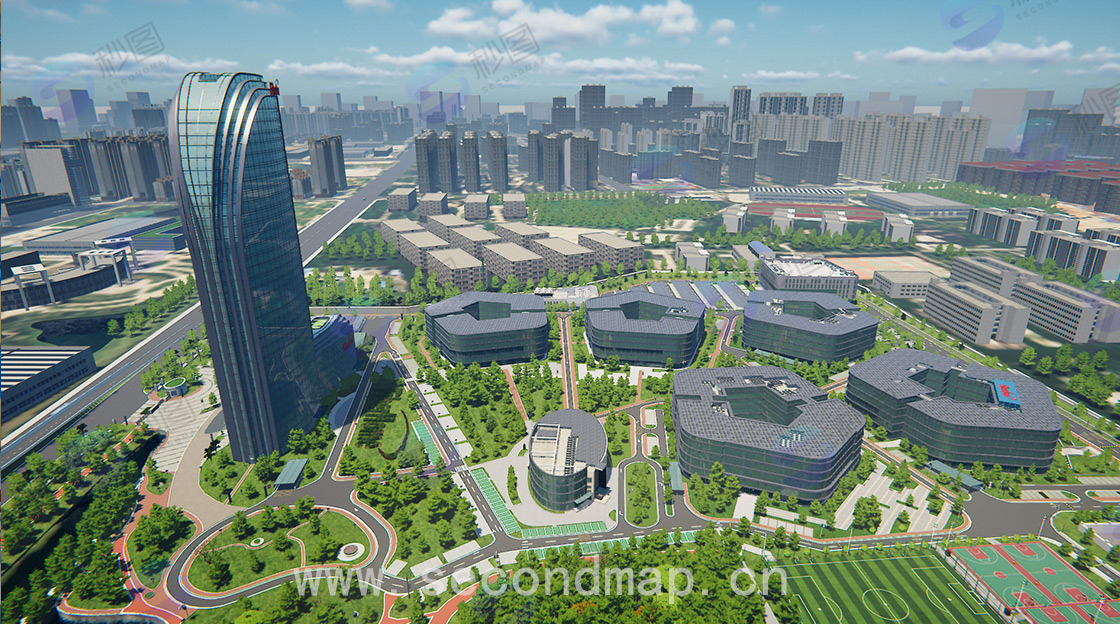

Kunling Smart Factory

Focusing on the construction needs of the Kunling Digital Factory, we provide full-chain 3D modeling services, covering core scenarios such as digital factory 3D modeling, workshop 3D modeling, and equipment 3D modeling. Utilizing L3 and L4 level high-precision modeling technologies, we create a professional factory digital twin platform. Tailored to the factory's production characteristics, the L3 level model accurately recreates the workshop layout, production line arrangement, and equipment appearance structure, clearly presenting spatial relationships; the L4 level model deepens the understanding of internal equipment components, pipeline connections, and operating mechanisms, achieving a full-dimensional digital replication of the equipment.

Based on this digital twin foundation, functions such as production data monitoring, equipment operation and maintenance management, and process simulation optimization can be integrated. It maps the factory's physical state in real time, helping the digital factory achieve visualized control of production processes, early prediction of equipment failures, and efficient optimization of resource allocation, effectively improving production efficiency and management accuracy, and providing solid 3D technology support for the factory's digital transformation and intelligent upgrade.