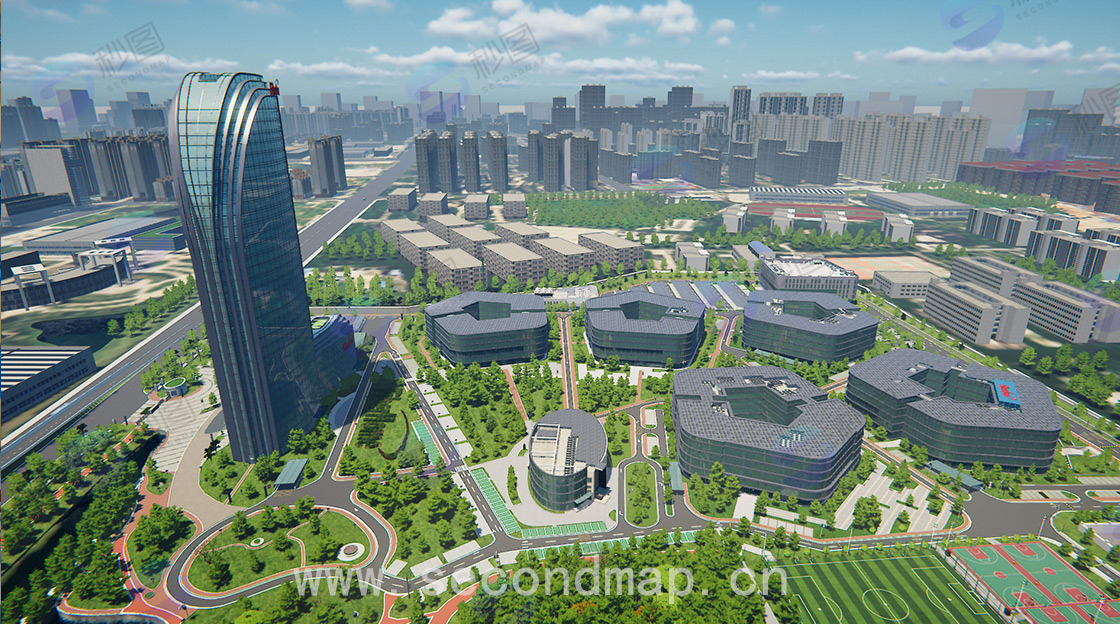

Baowu Group Shaoguan Iron and Steel Plant

We successfully delivered a high-precision 3D modeling project for steel plant equipment. The project utilized 3D laser point cloud scanning and L2 and L3 level modeling methods, focusing on key areas such as gas pipelines, conveyor belts, and related equipment. The lightweight models were rendered and presented in a browser, enabling digital operation and maintenance through the platform. This steel plant covers an area of 6 square kilometers, with approximately 0.5 square kilometers designated for 3D laser scanning modeling. Other areas of the steel plant were modeled using drone oblique photogrammetry.

We specializes in the digital construction of steel plants, providing full-scene 3D technology solutions. Its core services cover steel plant 3D modeling, factory 3D modeling, pipeline 3D modeling, and 3D site plan drawing, helping steel companies achieve visualized upgrades to their production scenarios. Leveraging 3D laser scanning and pipeline laser scanning technologies, the project accurately collected physical data on the steel plant's structure, production equipment, and pipeline routes. Combined with oblique photogrammetry technology, it reconstructed the overall topography and building layout of the plant area, ensuring that the 3D model accurately matches the complex production environment of the Baowu Group steel plant, clearly presenting key details such as equipment connections, pipeline nodes, and plant spatial distribution. By integrating global information of the steel plant through customized 3D master plans, the results can be widely applied to scenarios such as steel plant planning and renovation, equipment operation and maintenance, and safety inspection. It replaces traditional two-dimensional drawings, breaks down information barriers, improves production management efficiency and risk control capabilities, provides professional technical support for the digital transformation of Baowu Group and the steel industry, and promotes the development of steel production towards intelligence and efficiency.