Xinyu Iron and Steel

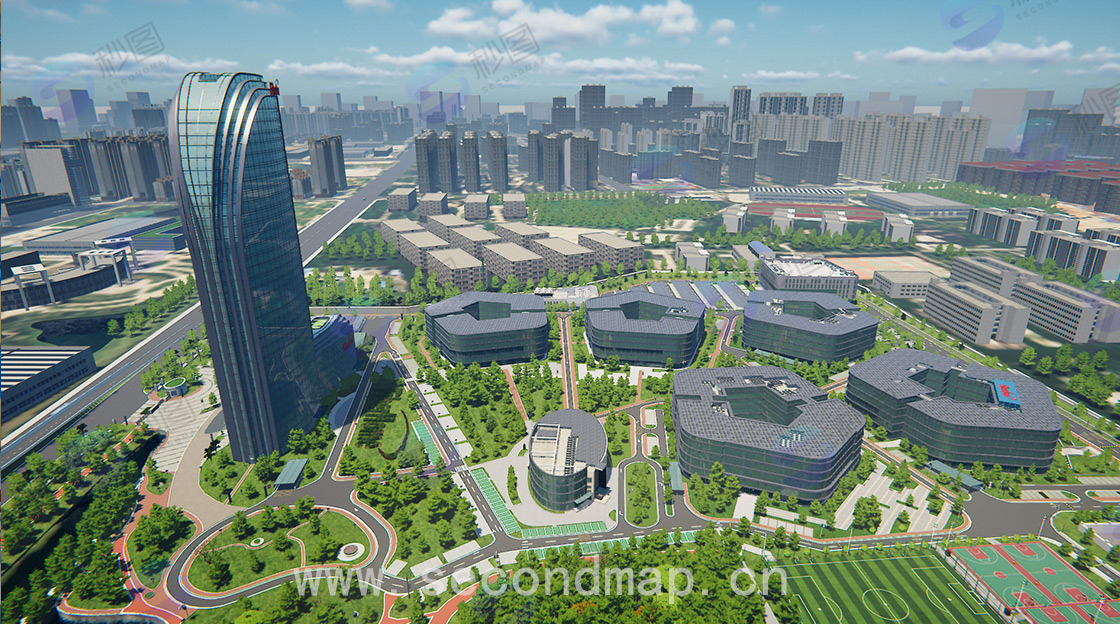

Focusing on the digital construction needs of the Xinyu Steel Plant (covering an area of approximately 15 square kilometers), we provide a professional oblique photogrammetry solution. Centered on drone oblique photogrammetry 3D modeling, and combining DJI aerial photography technology with drone 3D modeling capabilities, we efficiently complete the entire 3D modeling process for the steel plant. Addressing the characteristics of the Xinyu Steel Plant—its vast area, dense equipment, and complex environment—we utilize DJI professional aerial photography equipment to collect image data from multiple angles, accurately capturing details of core scenes such as plant buildings, production equipment, pipelines, and storage yards.

The 3D model built using oblique photogrammetry technology achieves a 1:1 realistic replica of the plant area, not only restoring the surface morphology and building appearance but also clearly presenting the spatial layout of equipment and production lines. This model can seamlessly integrate with the steel plant's digital twin, intelligent operation and maintenance, and safety monitoring systems, helping Xinyu Steel optimize plant planning, improve equipment inspection efficiency, and reduce safety risks. It provides high-precision, high-efficiency spatial data support for the digital transformation of steel enterprises, driving the upgrade of traditional steel plants to smart factories.