3D technical solution for equipment operation and maintenance digital twin platform

1. Project Background

In the era of Industry 4.0, efficient operation and maintenance of factory equipment is crucial for ensuring production continuity and improving productivity. Digital twin technology provides an innovative solution for factory equipment operation and maintenance. By constructing virtual models corresponding to real equipment, it reflects equipment status in real-time and achieves full lifecycle management of equipment. This solution aims to build a digital twin platform for factory equipment operation and maintenance, integrating functions such as factory equipment visualization, equipment management, equipment operation status monitoring, equipment alarms, equipment work order management, equipment inspection visualization, and camera position interaction, thereby enhancing the intelligence level of factory equipment operation and maintenance.

2. Requirement Analysis

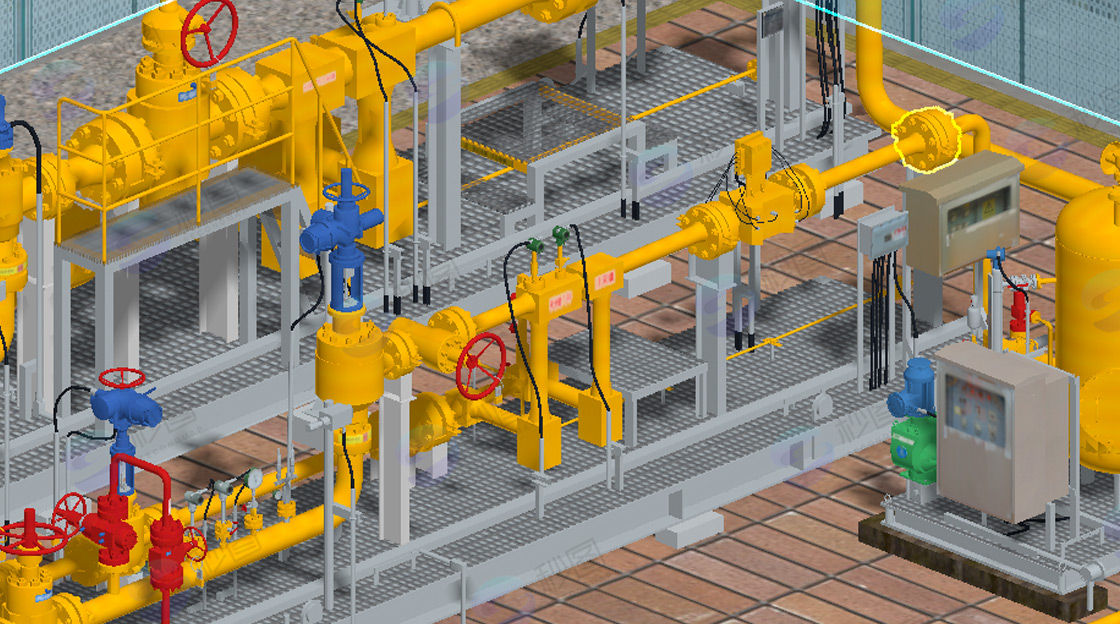

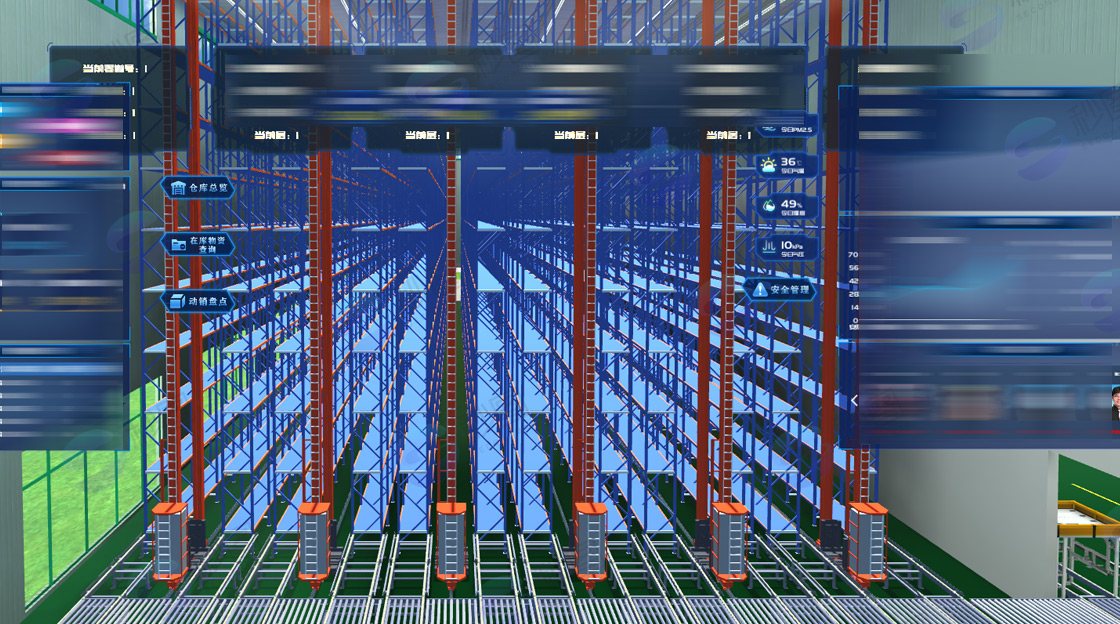

1. Factory Equipment Visualization: Intuitively display the appearance, position, and layout of various equipment in the factory in the form of 3D models.

2. Equipment Management: Implement entry, editing, querying of equipment information, and equipment ledger management.

3. Equipment Operation Status: Real-time acquisition of equipment operating parameters, such as temperature, speed, vibration, etc., and dynamic display of equipment operation status in the 3D scene.

4. Equipment Alarms: Timely issuance of alarm information when equipment operating parameters exceed normal ranges or faults occur, and highlighting alarm equipment in the 3D scene.

5. Equipment Work Orders: Create, assign, track, and manage equipment maintenance work orders, recording the maintenance process and results.

6. Equipment Inspection Visualization: Plan inspection routes, display inspector positions and inspection progress in real-time, and record inspection data.

7. Camera Position Interaction: Click on camera icons in the 3D scene to view real-time monitoring footage from corresponding cameras, assisting in equipment operation and maintenance monitoring.

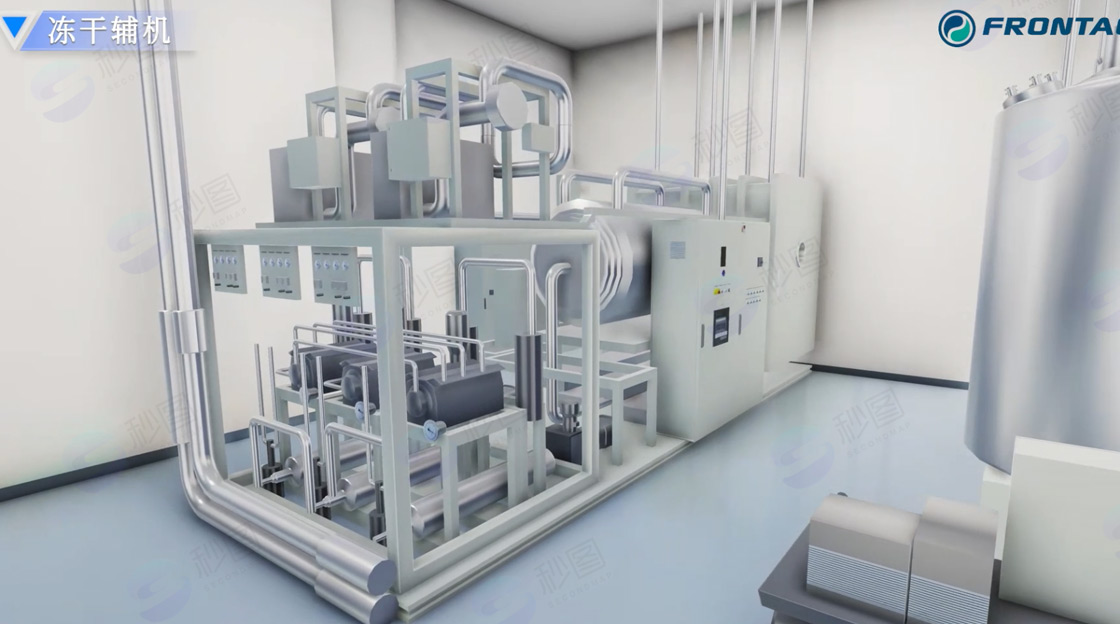

3. 3D Modeling

Data Collection

Obtain precise dimensions, shape, and structural information of equipment through field measurements, equipment drawings, CAD files, and other methods.

Collect visual feature data such as appearance materials and colors of equipment.

Modeling Software Selection

It is recommended to use professional 3D modeling software such as SolidWorks and CATIA, which have powerful functions in industrial design and mechanical modeling and can accurately create complex equipment models. For scene construction and overall layout, 3ds Max or Blender can be combined for optimization to enhance the visual effects and rendering performance of the scene.

Model Creation Process

First, based on equipment structure and functional modules, disassemble the equipment into multiple sub-components and model them separately. For example, for a complex machine tool, models of components such as the bed, spindle box, and worktable can be created separately.

During the modeling process, strictly create according to actual dimensions and proportions to ensure model accuracy. At the same time, process model details, such as adding equipment labels and nameplates.

After completing the modeling of each component, assemble them in 3D software to simulate the actual assembly state of the equipment, checking assembly relationships and motion interference between components.

Apply material and texture mapping to equipment models, setting material properties such as metal, plastic, and rubber according to the actual appearance of the equipment to make the model more realistic.

Construct factory scene models, including factory buildings, floors, passages, etc., place equipment models in appropriate positions, and form a complete factory equipment layout scene.

4. Technical Implementation

Development Platform Selection

Select Unity or Unreal Engine as the development engine for the digital twin platform. Unity has good cross-platform capabilities and rich plugin resources, with a relatively short development cycle, suitable for rapid iterative development; Unreal Engine excels in graphics rendering and can present high-quality visual effects, making it more suitable for projects pursuing ultimate visual presentation. The choice can be made based on project requirements and team technical capabilities.

Data Collection and Transmission

Equipment Operation Data Collection: Install various sensors on equipment, such as temperature sensors, pressure sensors, vibration sensors, etc., to collect equipment operating parameters in real-time. Transmit sensor data to the data acquisition server through industrial Ethernet, wireless sensor networks (WSN), or field buses (such as Profibus, Modbus, etc.).

Equipment Status Data Collection: Use the equipment's own control system or PLC (Programmable Logic Controller) to obtain equipment operation status information, such as equipment start/stop status, fault codes, etc. Transmit this data to the data acquisition server through communication protocols (such as OPC UA).

Personnel Location Data Collection: For equipment inspectors, adopt Bluetooth positioning, UWB (Ultra-Wideband) positioning and other technologies, equip inspectors with positioning tags, collect their location information in real-time, and transmit it to the platform through wireless networks.

Data Transmission Protocol: Adopt the MQTT (Message Queuing Telemetry Transport) protocol for data transmission, which has characteristics such as lightweight, low power consumption, and high reliability, suitable for ensuring data real-time and stability in complex factory network environments. At the same time, combine WebSocket protocol to achieve real-time bidirectional communication for equipment status updates, alarm push notifications, and other functions.

Database Selection

Select relational database MySQL to store structured data such as equipment basic information, equipment ledgers, work order information, and personnel information, facilitating data management, querying, and statistical analysis.

For real-time and historical data of equipment operation, which have time-series characteristics, select time-series databases such as InfluxDB for storage. InfluxDB has efficient read/write performance and flexible query functions in processing large-scale time-series data, meeting the needs for rapid storage and querying of equipment operation data.

Function Implementation

Equipment Visualization: Import the created 3D equipment models and factory scene models into the development platform, and implement model loading, display, and interaction functions through coding. Users can zoom, rotate, pan, and other operations in the 3D scene to view various angles and details of the equipment.

Equipment Management: Develop equipment management module, provide equipment information entry, editing, querying and other functional interfaces. Store equipment information in MySQL database, and implement equipment information management and maintenance through database operations.

Equipment Operation Status Monitoring: Obtain equipment operation data from the data acquisition server, through data parsing and processing, display the equipment's operating parameters in real-time on the corresponding equipment model in the 3D scene, such as displaying equipment temperature, speed, pressure and other parameters in the form of numbers, gauges, progress bars, etc. At the same time, set different colors or animation effects according to equipment operation status to intuitively reflect whether the equipment operation status is normal.

Equipment Alarms: Set normal threshold ranges for equipment operating parameters, trigger equipment alarm function when collected data exceeds thresholds. In the 3D scene, highlight alarm equipment with flashing red icons or other prominent identifiers, and send alarm information to operation and maintenance personnel through pop-ups, sounds, etc. At the same time, store alarm records in the database for subsequent querying and analysis.

Equipment Work Order Management: Develop work order management module to implement work order creation, assignment, tracking, and closure functions. When equipment fails or requires maintenance, work orders can be created in the system, fill in fault descriptions, maintenance requirements and other information, and assign work orders to corresponding maintenance personnel. After receiving work orders, maintenance personnel can view work order details on mobile or computer terminals, and record maintenance processes and results. Work order status is updated in real-time, facilitating managers to track work order progress.

Equipment Inspection Visualization: Plan equipment inspection routes in the 3D scene, set starting and ending points for inspectors. Through personnel positioning data, display inspectors' positions and inspection progress in the 3D scene in real-time. During inspections, inspectors can record equipment inspection data through mobile devices, such as equipment appearance inspection conditions, presence of abnormal sounds, etc., and upload data to the platform. The platform analyzes inspection data and generates inspection reports.

Camera Position Interaction: Add camera models in the 3D scene and associate them with actual camera equipment. Obtain real-time video streams from cameras through video stream servers. When users click on camera icons in the 3D scene, pop up video windows to display real-time monitoring footage from corresponding cameras, assisting operation and maintenance personnel in remotely monitoring equipment operation conditions.

5. System Testing and Optimization

Function Testing: Conduct comprehensive testing of functions such as factory equipment visualization, equipment management, equipment operation status monitoring, equipment alarms, equipment work order management, equipment inspection visualization, and camera position interaction to ensure all functions operate normally and data is accurate.

Performance Testing: Simulate different scales of equipment quantities and data traffic to test system operation performance, including frame rate, response time, data transmission delay and other indicators. Optimize scene rendering algorithms, data transmission strategies, and database query statements to improve system operation efficiency and stability, ensuring the system can run smoothly under high load conditions.

Compatibility Testing: Test on different types of terminal devices (such as computers, tablets, phones) and operating systems (such as Windows, iOS, Android) to ensure the system has good compatibility and meets the usage needs of different users.

Security Testing: Conduct security vulnerability scanning on the system, strengthen user permission management, data encryption transmission and storage, and other security measures to prevent data leakage and illegal operations, ensuring system security.

User Feedback and Optimization: Collect user feedback during usage, optimize the system's interface design, operation process, etc., to enhance user experience. Continuously expand and improve system functions based on user needs and changes in actual business scenarios.

6. Project Implementation Plan

Phase 1: Complete 3D modeling of factory equipment and scenes, build the basic framework of the digital twin platform, time period [specific time interval 1].

Phase 2: Implement equipment management, equipment operation status monitoring, and equipment alarm functions, complete the construction of the data collection and transmission system, time period [specific time interval 2].

Phase 3: Develop equipment work order management and equipment inspection visualization functions, integrate camera position interaction function, time period [specific time interval 3].

Phase 4: Conduct system testing and optimization, train users, and officially launch the platform, time period [specific time interval 4].

7. Summary

Through detailed 3D modeling processes and comprehensive technical implementation planning, this solution constructs a powerful digital twin platform for factory equipment operation and maintenance. During implementation, it is necessary to continuously optimize and adjust the solution based on the actual situation of the factory and user needs to ensure the platform can effectively improve the efficiency and intelligence level of factory equipment operation and maintenance, providing strong support for the factory's safe production and efficient operation.