Technical Solution for 3D Platform for Safety and Emergency Response in Chemical Plants

1. Project Background

The chemical plant production environment is complex with numerous safety risks. Building a three-dimensional platform for chemical plant safety emergency response can intuitively present the factory's operating status, timely identify and handle safety hazards, which is of great significance for protecting personnel life safety, reducing property losses, and improving emergency response efficiency. This solution aims to create a three-dimensional scenario platform with functions such as factory risk zoning, four-color maps, real-time equipment data, electronic fence identification, personnel positioning, vehicle positioning, camera position interaction, fire alarm, and emergency early warning, to enhance the safety management level of chemical plants.

2. Requirement Analysis

Factory Risk Zoning: Divide risk levels based on the danger level of different areas in the chemical plant, and clearly display them in the three-dimensional scene.

Four-Color Map: Use red, yellow, blue, and green colors to intuitively present the overall risk distribution of the factory, facilitating quick identification of high-risk areas.

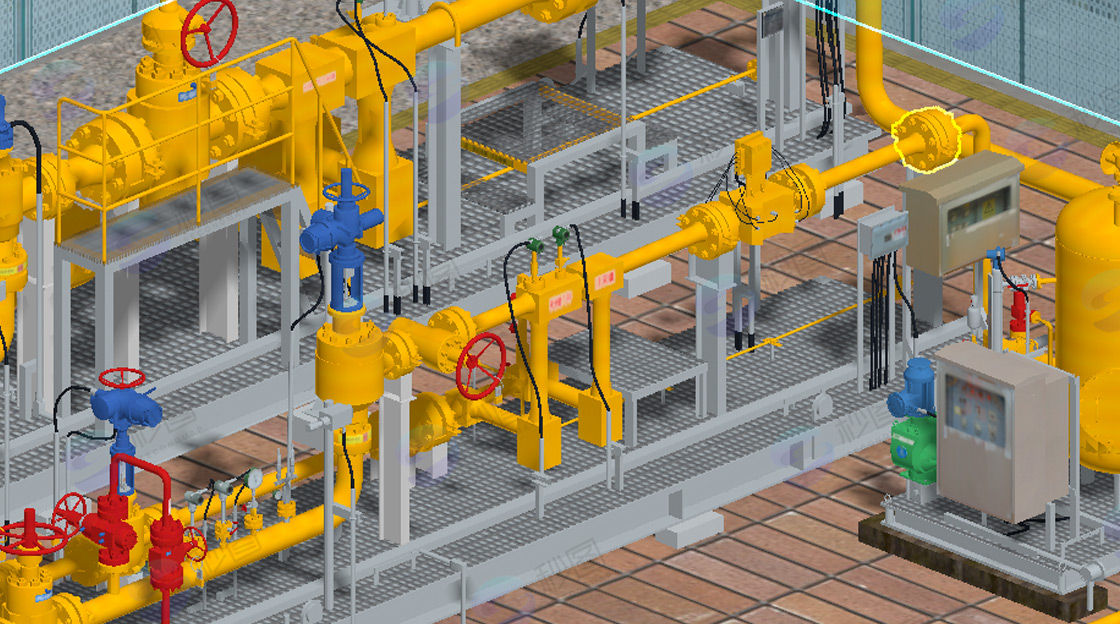

Real-Time Equipment Data: Real-time acquisition of operating parameters of key equipment, such as temperature, pressure, flow rate, etc., and display at the corresponding equipment in the three-dimensional scene.

Electronic Fence Identification: Set up electronic fences for specific dangerous areas, triggering alarms when personnel or vehicles enter without authorization.

Personnel Positioning: Real-time tracking of personnel positions within the factory to enable rapid rescue in emergencies.

Vehicle Positioning: Position transportation vehicles, forklifts, etc. within the factory to avoid collision accidents.

Camera Position Interaction: Click on camera icons in the three-dimensional scene to view real-time surveillance footage, assisting in security monitoring.

Fire Alarm: When the fire protection system detects fire hazards (such as smoke, high temperature, etc.), accurately locate the alarm position in the three-dimensional scene and issue an alarm.

Emergency Early Warning: Issue emergency early warnings in advance based on abnormal equipment data, risk monitoring, and other information to gain time for emergency response.

3. Technology Selection

3D Modeling Software: Use 3ds Max or Blender for creating three-dimensional models of the chemical plant. 3ds Max has extensive experience in industrial modeling with abundant plugin support; Blender is open-source software with powerful modeling and rendering capabilities, and can be selected based on project budget and team familiarity.

Platform Development Engine: Adopt Unity or Unreal Engine. Unity has strong cross-platform capabilities and a relatively short development cycle, suitable for rapid iterative development; Unreal Engine excels in graphics rendering and can create realistic visual effects, suitable for scenarios with extremely high graphic quality requirements.

Positioning Technology:

Personnel Positioning: Adopt UWB (Ultra-Wideband) positioning technology with high precision, enabling high-accuracy indoor and outdoor positioning. Equip personnel with positioning tags to obtain real-time location information.

Vehicle Positioning: Combine GPS and Bluetooth positioning technologies. Install positioning devices on vehicles to meet outdoor driving positioning needs while achieving accurate indoor positioning to ensure accurate vehicle location tracking.

Data Collection and Transmission:

Use sensors to collect real-time equipment data, fire alarm data, etc., and transmit data to the platform through industrial Ethernet, wireless sensor networks (WSN), and other methods.

Adopt MQTT protocol for data transmission, which is lightweight and low-power, suitable for ensuring data real-time and stability in the complex network environment of chemical plants.

Database: Select InfluxDB to store time-series data such as equipment operating parameters, which performs excellently in processing time-series data; use MySQL to store structured data such as personnel information, vehicle information, and basic equipment information, facilitating data management and querying.

Visualization Framework: Introduce visualization frameworks such as Echarts to display four-color maps, real-time equipment data charts, etc., enhancing data visualization effects.

4. Data Collection and Processing

| Factory Model Data | Obtain detailed information such as factory buildings and equipment layout through field measurements, factory CAD drawings, and other methods, and import into 3D modeling software to build accurate 3D models. |

| Real-Time Equipment Data | Install sensors on key equipment to collect parameters such as temperature, pressure, and flow rate in real-time. After data cleaning and preprocessing, store in InfluxDB database and transmit to the 3D platform for real-time display. |

| Personnel and Vehicle Location Data | Bluetooth, GPS, UWB, and other positioning devices collect real-time location information of personnel and vehicles. After coordinate conversion and data processing, update location display in the 3D scene in real-time. |

| Fire Alarm Data | When fire sensors detect abnormal conditions such as smoke and high temperature, transmit alarm signals to the platform. The platform parses the signals and accurately locates the alarm position in the 3D scene. |

| Risk Assessment Data | Comprehensively consider factors such as equipment operating status, hazardous substance storage volume, and personnel activities to conduct risk assessment calculations, generate risk zones and four-color map data, and display on the platform. |

5. Three-Dimensional Scene Construction Process

Factory Model Creation:

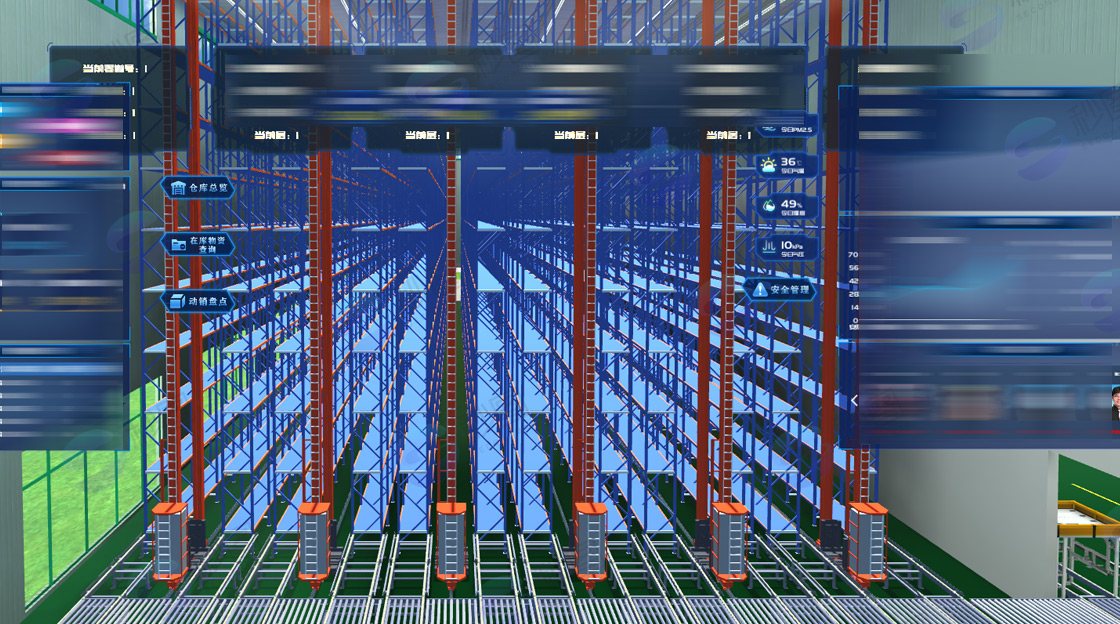

Using 3D modeling software, create models of factory buildings, equipment, roads, etc., according to the actual layout and dimensions of the factory, ensuring the accuracy and detail of the models.

Process materials and lighting effects for the models to make them closer to real scenes and enhance visual effects.

Risk Zoning and Four-Color Map Drawing:

Based on risk assessment data, divide different areas into risk levels in the 3D scene and differentiate them with different colors or identifiers.

Generate a four-color map based on risk zoning data, overlay it on the 3D scene, and intuitively display the overall risk distribution of the factory.

Electronic Fence Setup: In the 3D scene, draw electronic fence areas for dangerous areas (such as chemical storage areas, high-voltage equipment areas, etc.), set intrusion trigger rules and alarm mechanisms.

Real-Time Equipment Data Display: Associate equipment models with real-time data, and dynamically display equipment operating parameters on equipment models in the form of numbers, charts, etc.

Personnel and Vehicle Positioning Implementation: Connect personnel and vehicle positioning data to the 3D platform. Through coordinate mapping, display their positions in real-time in the 3D scene, and set trajectory display functions to facilitate viewing of movement paths.

Camera Position Interaction Setup: Add camera models in the 3D scene and establish connections with actual camera equipment. When clicking on camera models, obtain and display real-time surveillance footage through the video stream server.

Fire Alarm and Emergency Early Warning Integration: Interface the fire alarm system and emergency early warning system with the 3D platform. When receiving alarm or early warning signals, display the alarm location and early warning information in a prominent manner (such as flashing red lights, pop-up prompts, etc.) in the 3D scene, and issue sound alarms.

6. System Testing and Optimization

Functional Testing: Conduct comprehensive testing of functions such as factory risk zoning, four-color map display, real-time equipment data display, electronic fence alarm, personnel positioning, vehicle positioning, camera position interaction, fire alarm, and emergency early warning to ensure all functions operate normally and data is accurate.

Performance Testing: Simulate system loads under different scenarios, test performance indicators such as system frame rate, response time, and data transmission delay, optimize scene rendering algorithms and data transmission strategies to ensure stable and smooth system operation in complex environments.

Compatibility Testing: Test on different types of terminal devices (such as computers, tablets, large-screen displays) and operating systems to ensure system compatibility and meet the usage needs of different users.

Security Testing: Conduct security vulnerability scanning on the system to ensure secure data transmission and reasonable user permission management, preventing data leakage and unauthorized operations.

User Feedback and Optimization: Collect user feedback during usage, optimize system interface and operation processes to enhance user experience.

7. Project Implementation Plan

Phase 1: Complete the creation of the chemical plant 3D model and preliminary drawing of risk zoning and four-color maps, time period [specific time interval 1].

Phase 2: Implement real-time equipment data collection and display, and electronic fence setup, time period [specific time interval 2].

Phase 3: Complete integration of personnel positioning and vehicle positioning functions, and build camera position interaction function, time period [specific time interval 3].

Phase 4: Integrate fire alarm and emergency early warning functions, and conduct system testing and optimization, time period [specific time interval 4].

8. Summary

This solution creates a comprehensive three-dimensional platform for chemical plant safety emergency response through reasonable technology selection, detailed data collection and processing procedures, and comprehensive three-dimensional scene construction steps. During implementation, the solution needs to be continuously optimized and adjusted according to the actual situation of the chemical plant and user requirements to ensure the platform can effectively enhance the safety management and emergency response capabilities of chemical plants.