3D modeling of urban integrated utility tunnels

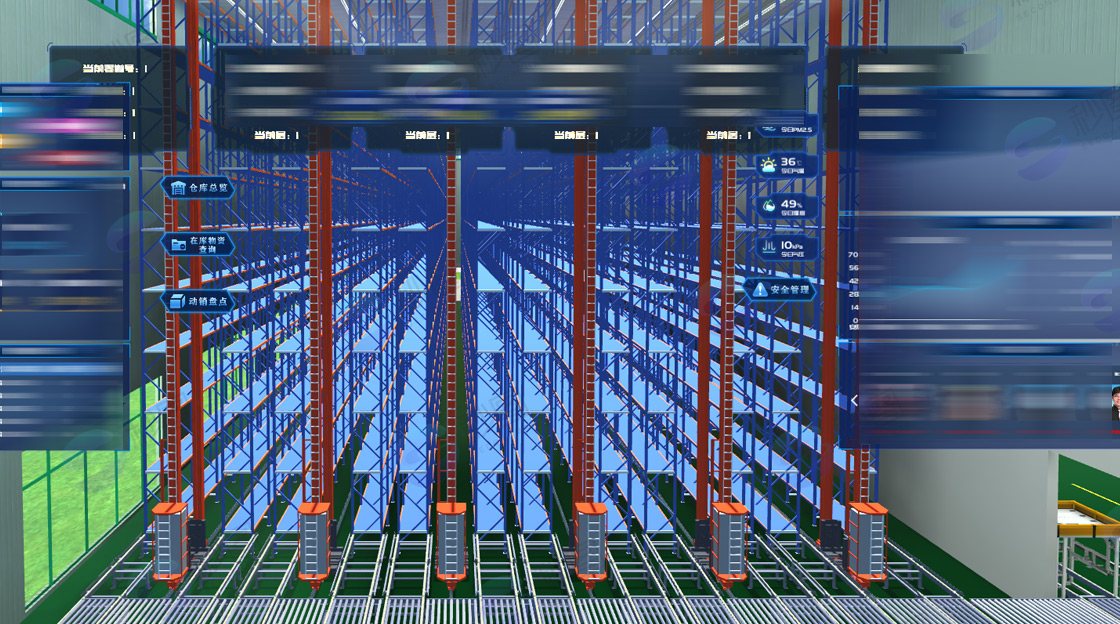

During the operation and maintenance phase, the three-dimensional model of the utility tunnel can be combined with real-time monitoring data to achieve real-time monitoring and management of the tunnel. Management personnel can quickly locate equipment failure positions through the model for repair and maintenance, improving the efficiency and level of operation and maintenance management.

The main 3D technologies used in comprehensive utility tunnel 3D modeling include:

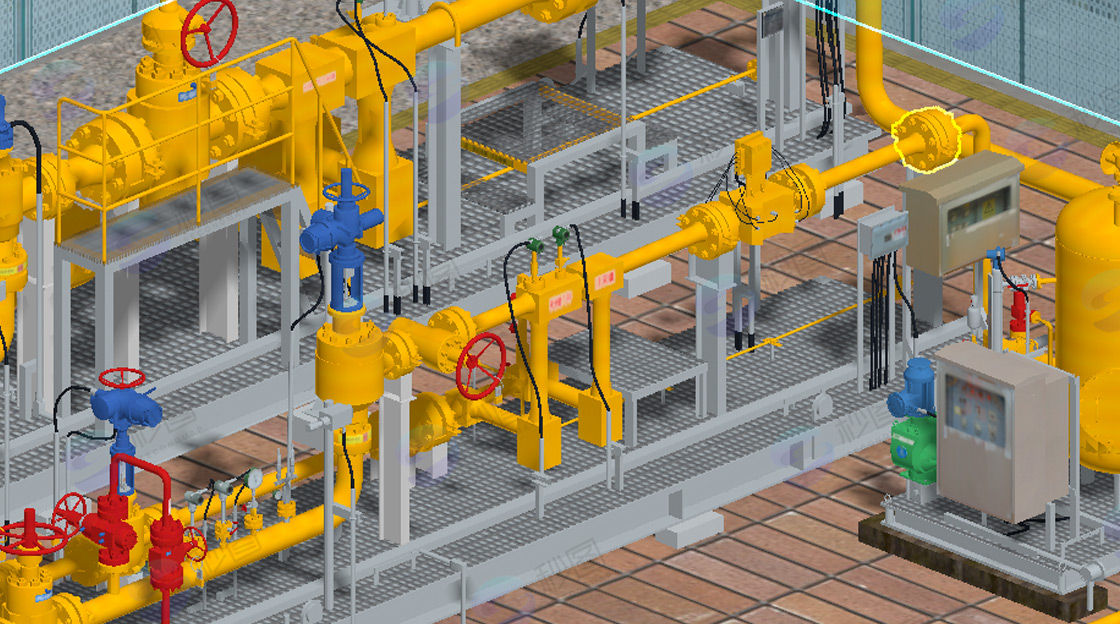

1. Building Information Modeling (BIM) technology is one of the commonly used technologies in comprehensive utility tunnel 3D modeling. It can integrate various information of the comprehensive utility tunnel, such as structure, pipelines, equipment, etc., into a 3D model, achieving information sharing and collaborative management. Through BIM technology, designers can design and optimize the tunnel in a virtual environment, construction personnel can use the model for construction guidance, and operation and maintenance personnel can use the model for equipment management and maintenance.

2. Geographic Information System (GIS) technology can combine the geographic location information of the comprehensive utility tunnel with the 3D model to provide more comprehensive spatial information. It can conduct detailed analysis and display of the terrain, landform, and underground pipelines along the tunnel, helping management personnel better understand the surrounding environment of the tunnel and providing decision support for the planning, design, and operation of the tunnel.

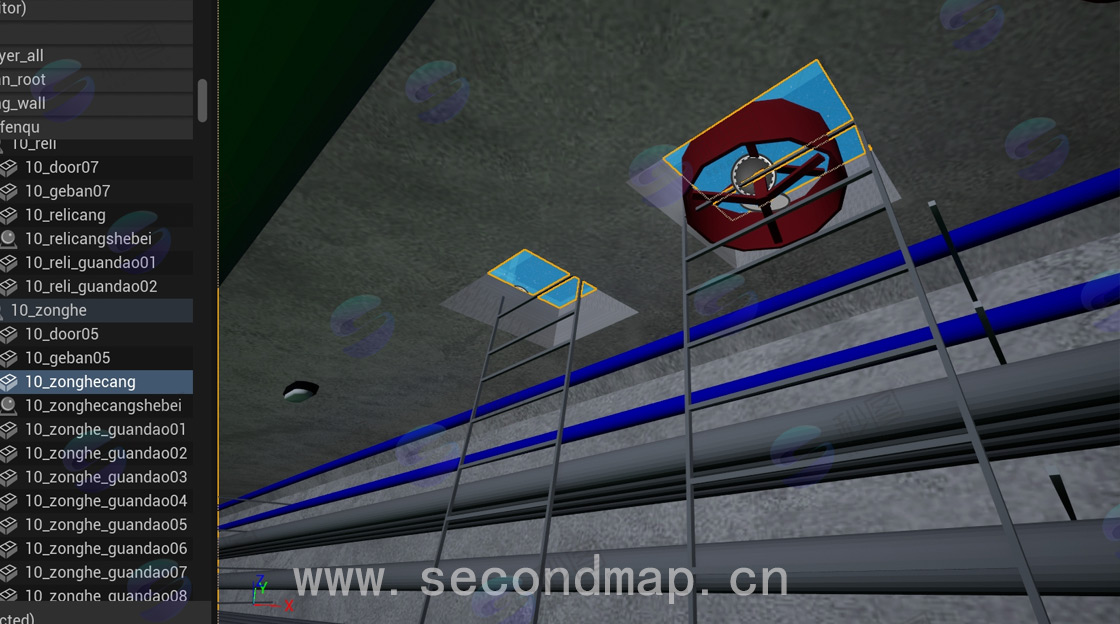

3. Laser scanning technology can quickly and accurately obtain the spatial data of the comprehensive utility tunnel. By emitting laser beams and measuring the time and intensity of reflected light, it generates 3D point cloud data of the tunnel. These point cloud data can serve as the basis for 3D modeling, used to construct accurate models of the tunnel. Especially for existing tunnel modeling and renovation projects, laser scanning technology can greatly improve the efficiency and accuracy of modeling.

Utility Tunnel Point Cloud

Comprehensive utility tunnel 3D modeling process:

1. Collect various data related to the comprehensive utility tunnel, including the tunnel's design drawings, terrain data, geological information, pipeline information, etc. These data are the foundation of 3D modeling, and their accuracy and completeness directly affect the quality of the model.

2. Based on the collected data, use professional 3D modeling software, such as Revit, 3dsmax, etc., to construct the 3D model of the comprehensive utility tunnel. During the modeling process, it is necessary to follow certain rules and standards to accurately model each part of the tunnel, including the main structure of the tunnel, internal pipelines, equipment, etc.

3. Integrate the constructed models of each part to form a complete 3D model of the comprehensive utility tunnel. Then optimize the model, check if there are any conflicts, errors, or unreasonable places in the model, and make adjustments and modifications.

4. Apply the 3D model to various stages of the comprehensive utility tunnel, including planning, design, construction, and operation and maintenance. At different stages, update and maintain the model according to actual needs to ensure that the model can accurately reflect the actual situation of the tunnel.