Digital Twin 3D Model Production Standards

Digital twin fully utilizes physical models, sensor updates, operational history and other data to integrate multi-disciplinary, multi-physical, multi-scale, and multi-probability simulation processes, completing mapping in virtual space to reflect the entire lifecycle process of corresponding physical equipment. Digital twin has many requirements for 3D models in terms of accuracy, data, and functionality, as follows:

Accuracy Requirements

The geometric shape of the 3D model must be highly consistent with the real physical object. Subtle structural features and dimensional differences may affect the accuracy of the digital twin. For example, in the digital twin of an aero engine, the accuracy of geometric parameters such as blade shape and angle must reach the micron level to accurately simulate the flow field and stress distribution when airflow passes through the blades.

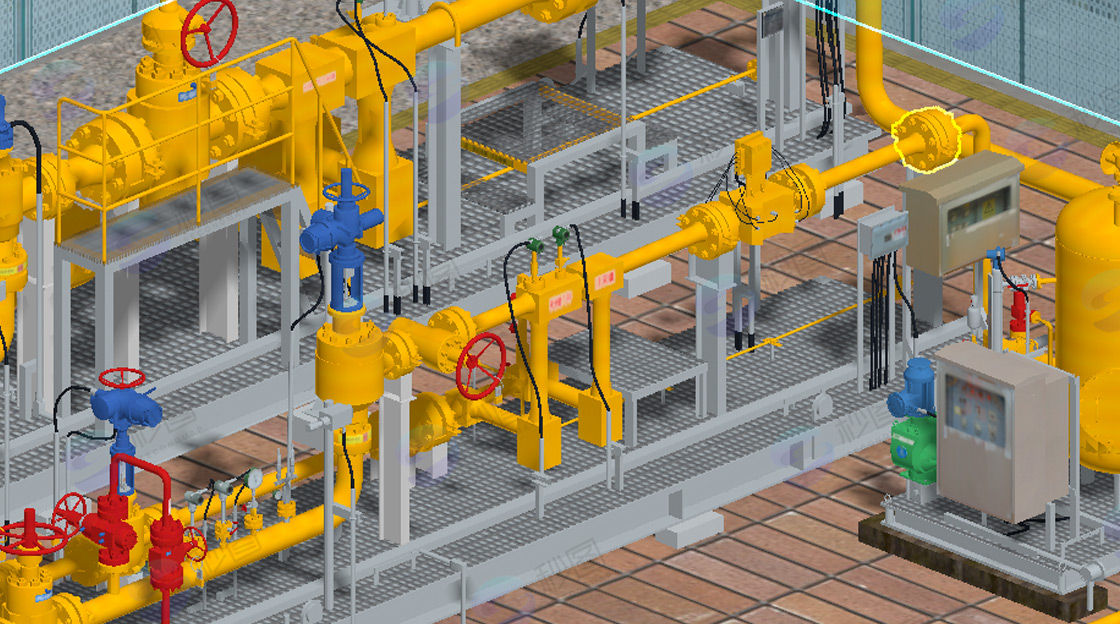

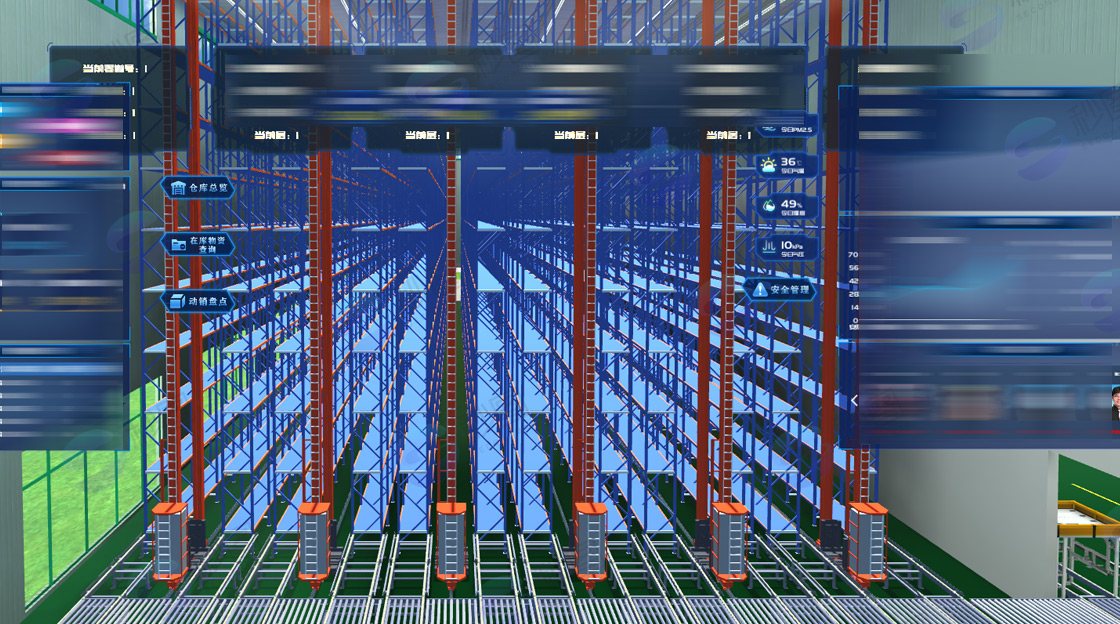

The relative positions of each component in the model and the absolute position of the model in space need to be accurately determined. In the digital twin of a smart factory, the 3D model positions of production equipment must correspond precisely to the actual positions in the factory. Excessive deviation will cause errors in logistics route planning and equipment collaboration simulation.

Data Requirements

The 3D model needs to contain complete physical object information, including appearance, internal structure, material properties, etc. Taking automotive digital twin as an example, it is necessary to not only construct a 3D model of the car shell, but also include detailed models of internal components such as the engine and transmission, as well as material parameters and mechanical properties of each component.

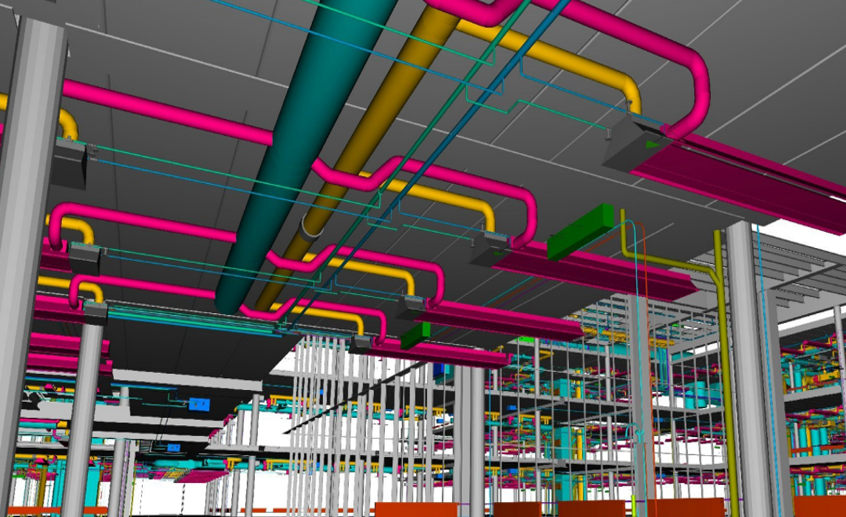

The model should have rich semantic information so that computers can understand and process it. For instance, in Building Information Modeling (BIM), each component's 3D model should not only have geometric data, but also include semantic information such as component name, type, function, and manufacturer, facilitating information querying, analysis, and management in the digital twin system.

It should be able to integrate data from different data sources, such as CAD data, sensor data, and surveying data. For example, in urban digital twins, it is necessary to integrate urban terrain surveying data, building CAD design data, and environmental data collected by various sensors into the 3D model to comprehensively reflect the real state of the city.

Performance Requirements

To improve the operational efficiency and response speed of digital twin systems, 3D models need to be lightweighted to reduce data volume while maintaining key features and accuracy of the model. In the digital twin of large complex equipment, model simplification and compression technologies are used to ensure the model can meet simulation analysis requirements while loading and running quickly on computers.

It should be able to update the model in real-time based on state changes of the physical entity and sensor data. In the digital twin of power systems, the 3D model of transmission lines needs to update model information such as thermal state and stress state in real-time based on sensor data such as current, voltage, and temperature to accurately reflect the operating state of the lines.

Functional Requirements

The 3D model should be able to support simulation and analysis of various physical processes, such as fluid simulation, structural mechanics simulation, and thermal simulation. In ship digital twins, fluid dynamics simulation of the hull 3D model can simulate ship navigation performance under different sea conditions, providing decision support for ship design and operation.

The model should have good interactivity to facilitate user interaction with the digital twin system. For example, in digital twin applications for virtual assembly training, users can operate the 3D model to perform virtual assembly and disassembly of components, and view interference situations and operational steps during the assembly process.

It should be compatible with other modules and software tools in the digital twin system. In a digital twin platform for intelligent manufacturing, the 3D model should be able to exchange data and collaborate with production planning and scheduling systems, quality inspection systems, and logistics management systems.

Other Requirements

As physical entities develop and digital twin application requirements increase, 3D models should be scalable to facilitate adding new functions and attributes.

It should follow relevant industry standards and specifications. In the industrial design field, 3D models should follow standards such as STEP and IGES to enable data exchange and sharing between different software and systems.